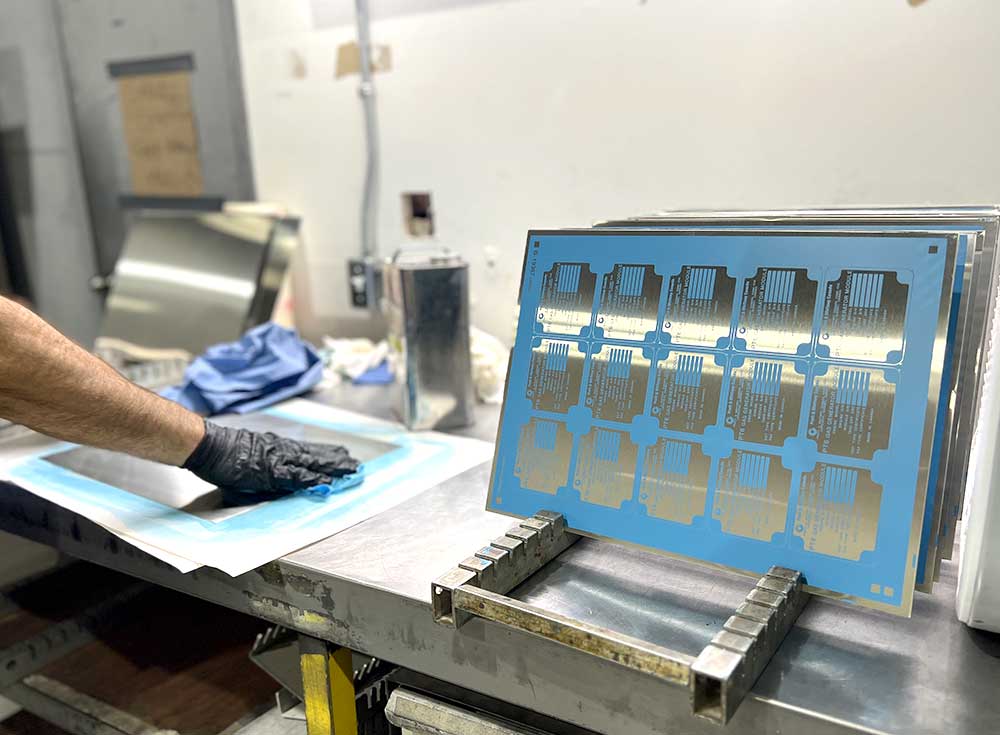

Laser Cutting Service For Aluminum & Stainless Steel

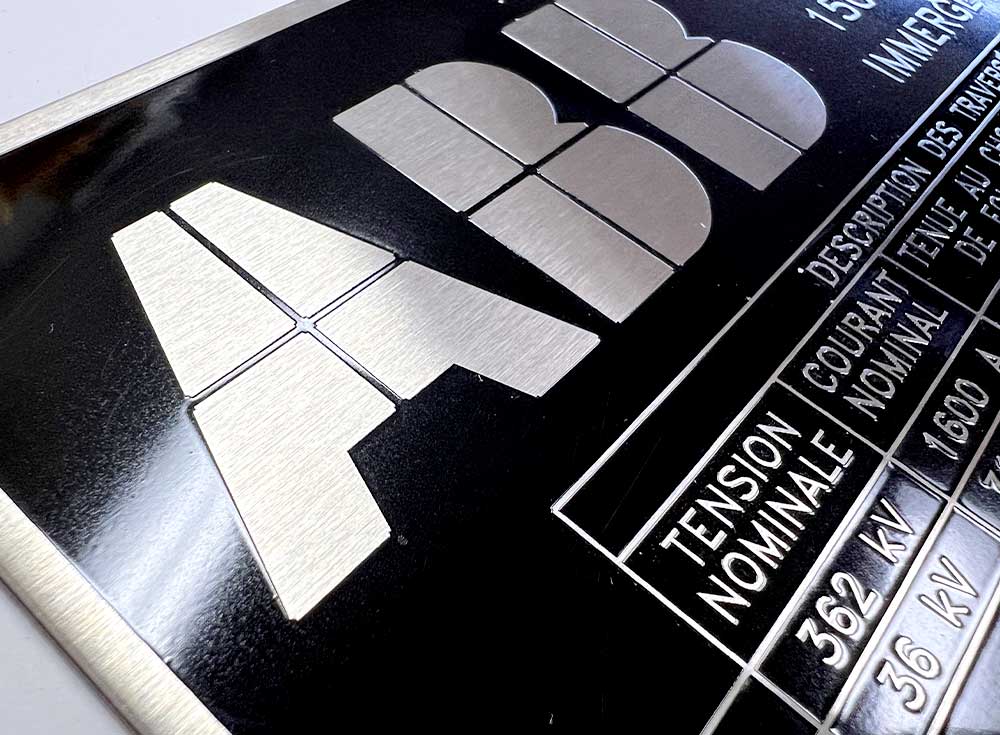

Take advantage of Idenco’s expertise and state-of-the-art equipment for precise cutting of your aluminum and stainless steel nameplates.

Take advantage of Idenco’s expertise and state-of-the-art equipment for precise cutting of your aluminum and stainless steel nameplates.

Find out how laser cutting will optimize the production of your parts.

Compared to traditional cutting, laser cutting is faster, with fewer production steps and therefore shorter lead times.

The extreme precision of our equipment enables us to meet and exceed your industry’s most demanding standards.

In addition to saving material thanks to its precision, laser cutting guarantees fewer rejects and fewer non-conformities.

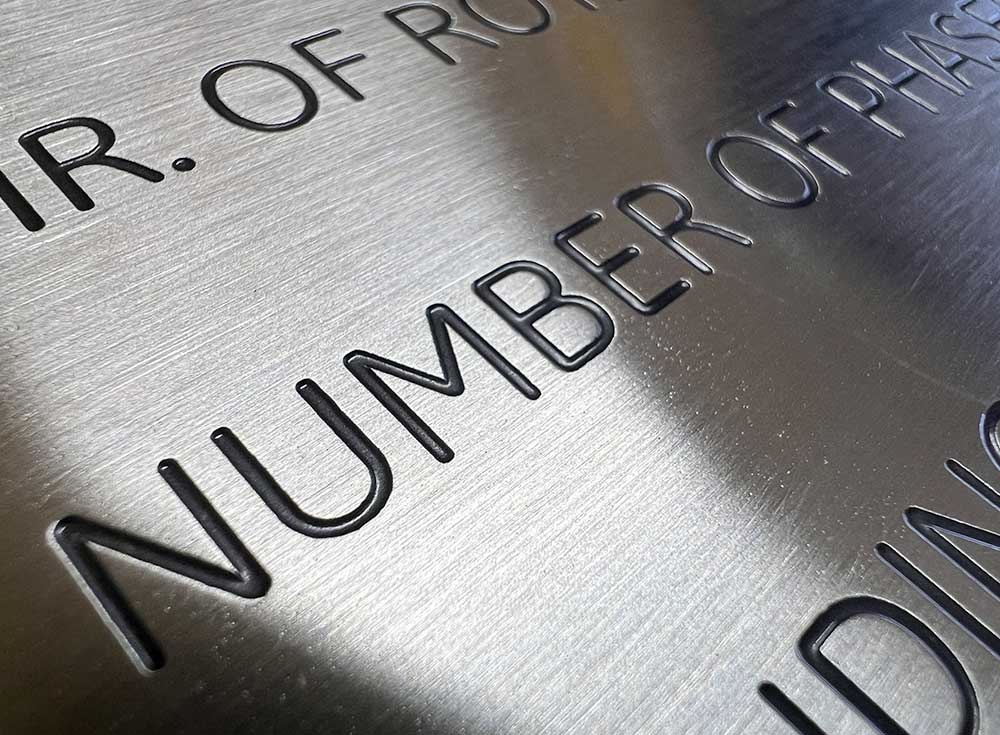

We can cut aluminum, stainless steel and galvanized steel.

Our equipment enables us to cut steel and aluminum up to ⅛’’ thick.

We can cut up to 46’’ inches x 46’’ inches.

Unlike rotary metal cutting, laser cutting requires no oil and produces less dust and noise, making it less harmful to the environment, and more pleasant for operators.

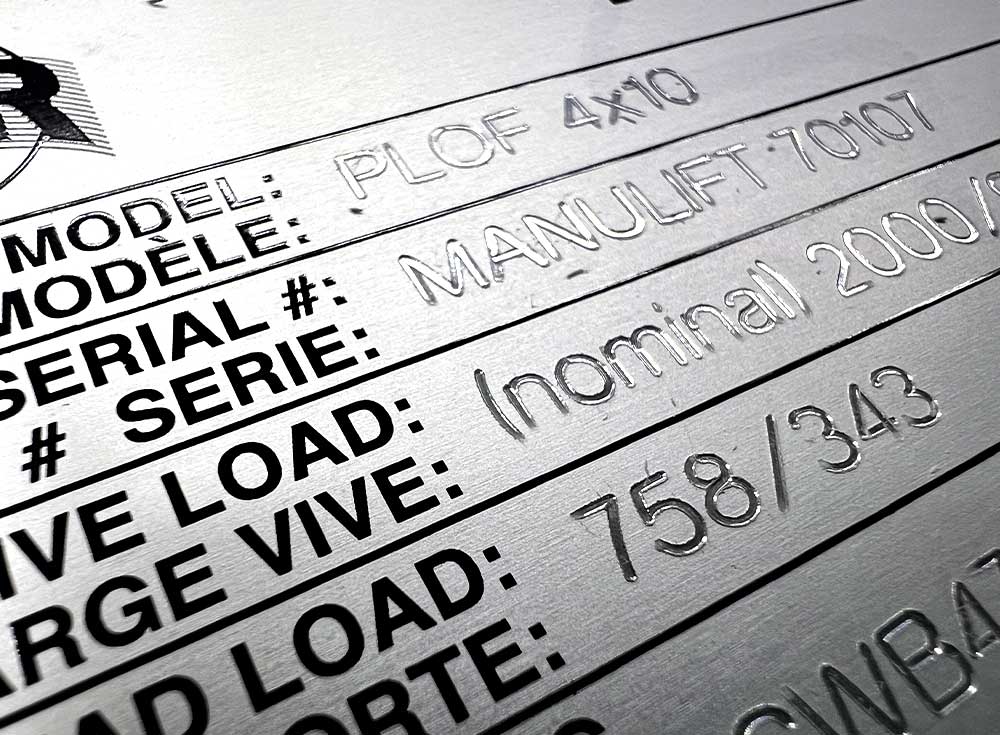

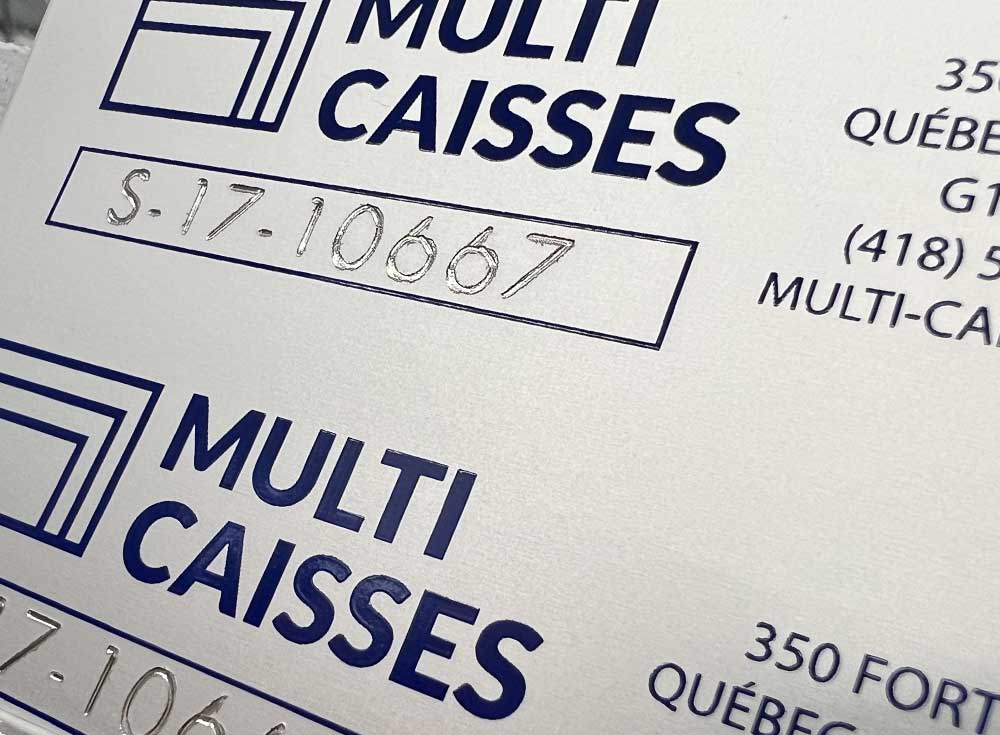

We offer several durable solutions for marking and engraving information on your industrial nameplates in aluminum, stainless steel and brass.

Need plastic nameplates? Idenco also offers laser engraving on Gravoply® and Lamicoïd® in a wide variety of colors and thicknesses.

We have the certifications you need to ensure that your nameplates meet the rigorous standards of your industry.